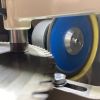

GRINDING MACHINE: TYP 3000 B

The sharpener is intended for saws with trapezoidal teeth for chipboards

It cuts the saw tooth rake and tooth clearance in one pass without having to adjust the saw blade

Technical data:

- Power supply 380-400V 50Hz

- Power consumption 500W

- Diamond grinding wheel

- Grinding wheel diameter 125 mm

- The rotation of the grinding wheel 6000 rpm (with the optimal cutting speed 39 m / s)

- Diameter of sharpened saws in the range of 100 - 600 mm

- CNC control in 3 axes

- Saw blade sharpening: rake angle and clearance angle

- Coolant cooled

- Cooling system tank capacity: 30 l

- Machine weight: 300 kg

- Dimensions: 1100x900x1400mm

Controller

The sharpener is equipped with a CNC control. The controller has a memory for 128 programs/ types of saws.

The latest software enables an accelerated sharpening process and even more accurate results. The saw teeth are perfectly sharpened and ready for further use.

The machine has a program for sharpening the same saws, e.g. multi-saw, without adjusting the saw blade again.

Sharpens the tooth rake and clearance angles, as well as trapezoidal teeth with a tilt of up to 45 ° to both sides - the grinding wheel turns automatically.

The sharpening of the rake and clearance angles is done with the saw setting up once without taking it off.

Machine description

In our sharpener, the grinding wheel reaches the tooth rake with a rapid feed and switches to working motion. The tooth is ready in one pass, which shortened the sharpening process by half. The quality of sharpening has improved even more due to the slower feed.

Example:

-> Saw with a diameter of 300 mm with 96 teeth machine blades with a rake angle of only 9 minutes, with a relief angle of a trapezoidal-flat tooth only 19 minutes.

This sharpening process significantly extends the life of the machine.

The machine works very energy-efficiently consuming only 0.5 kW per hour of work.

The use of an automatically twisted head with a grinding wheel in the sharpener enables sharpening of the clearance angle in saws with trapezoidal teeth in one pass. The head automatically turns to the desired - set angle, e.g. 45 °. The next flat tooth is lowered by a set value, e.g. 0.2 mm.

The use of a claw-type feeder ensures very precise feeding of the tooth to be sharpened under the grinding wheel. At the same time, it prevents the grinding wheel from colliding with the saw blade if the spacing of the teeth is different, which is particularly applicable in the case of regenerated saw blades.

The brake that keeps the saw from turning is supported by a pneumatic actuator. When feeding the next tooth, the brake releases the clamp, then the saw turns loosely, then after stopping it is firmly pressed against the anvil with a pneumatic cylinder. Such a process ensures more accurate feeding of the tooth under the grinding wheel, and during sharpening the saw is maximally blocked (it does not move during sharpening), which in the end has a positive effect on the quality of sharpening.

The use of a full housing of the sharpener prevents the cooling emulsion from splashing with the filings outside during the sharpening process.

After sharpening the saw, the sharpener automatically turns off the grinding wheels and the coolant pump.

The low power consumption of the machine during operation is also a big advantage. It consumes only 500W (for comparison, sharpeners from other manufacturers consume about 3500W).

58-533 Mysłakowice